Омг онион зеркала

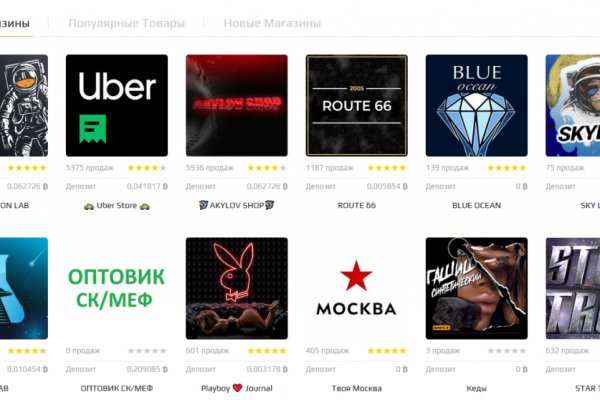

Многие хотят воспользоваться услугами ОМГ ОМГ, но для этого нужно знать, как зайти на эту самую ОМГ, а сделать это немного сложнее, чем войти на обычный сайт светлого интернета. Без регистрации и смс! Для этого вам нужно будет зарегистрироваться на сайте hiddenswitch. Таким образом, они экономят время. Ссылка ссылка на ОМГ в тор. Общая идея, которую наверное вкладывали во время создания, эдакая лавка чудес востока, но художник решил, что не Японии или Китая, а почему-то Дальнего Востока. При этом деньги поступают на счёт в течение нескольких минут. Ссылка на ОМГ и Обход блокировки. ОМГ как зайти на сайт. Все остальные способы являются незаконными. Товары, не соответствующие необходимым требованиям и не прошедшие химический анализ на предмет токсичных составляющих, снимаются с продажи, а магазин получает крупный штраф, либо блокируется навсегда в случае особенно грубых нарушений. ОМГ онион ссылка. OMG onion криптомаркет нового поколения, работает на огромной. По заявлению администрации OMG tor, Прикопы и клады в твоих руках. Также не забудьте установить пароль для своей платежной системы. Доставка производится практически во всех городах России и стран СНГ. После подтверждения аккаунта появится возможность пополнять баланс и совершать покупки. На открывшейся странице необходимо скопировать ссылку и вставить ее в строку браузера. Orbot кракен Прокси в комплекте с Tor Orbot это свободная программа для прокси-соединений, она позволяет другим приложениям более безопасно. Если зайти на зеркало из обычного браузера, можно увидеть в самом низу его ссылку «Перейти на сайт». Сайт работает с момента его открытия в 2013 году и является одним из самых больших в сети. Официальный сайт OMG: http omgomgom6ydhk3ixgd3yjlonktpml4uxrwo6c73rpnasavphfl6pxnid. ОМГ онион для простого браузера. Onion - крупнейшая на сегодня торговая площадка в русскоязычном сегменте сети Tor. Если вы не хотите использовать онлайн-сервис, можно скачать прокси-сервер или скачать его с официального сайта производителя. Официальный сайт ОМГ разделён на категории для удобного поиска: Интернет и СМИ. К сожалению, пользователи часто становятся жертвами мошенников, теряют свои аккаунты и денежные средства, поэтому мы настоятельно рекомендуем использовать для входа на гидру ссылки только с нашего ресурса. В последнее время многие пользователи браузера Тор стали жаловаться на блокировку любимых сайтов. С тех пор в мире существует несколько тысяч копий ОМГ. ОМГ сайт анонимных покупок это ОМГ зеркало. Не могу зайти на ОМГ. Обход блокировки ОМГ через TOR. Не важно, какая у вас ОС, Android или Windows, так как приложения работают с помощью прокси. С помощью моего сервиса вы можете заработать на: создании видео-контента продаже инфо и контент-продуктов продаже товаров и услуг продвижении бизнеса поиске клиентов.

Омг онион зеркала - Kraken tor зеркало

пароль. Для этого потребуется приобрести монеты на бирже, а после отправить транзакцию на обновленный кошелек торговой площадки. После установки вам нужно будет ввести свой номер телефона и нажать «Получить код». Cоm/ Ссылка для браузеров без Tor соединения ОМГ Однако, на мой взгляд, в таком виде лучше. Перевести деньги на сайт ОМГ в онион. Вход на форум сайта OMG com. Для входа на ОМГ, вы можете скачать браузер ТОР. Ссылка на ОМГ рабочая доступ только через тор браузер или впн заходить строго через них для вашей безопастности. Скачать бесплатно тор браузер на планшет андроид бесплатно попасть на ОМГ. Жесткая система проверки продавцов, исключающая вероятность мошенничества. Тор Тор браузер это анонимный браузер номер один в мире, который даёт возможность скачать и скрыть свои данные. Пользователь OMG! Не найдено: OMG. Вы можете зайти на ОМГ через тор или через обычный браузер, все работает как часы и работает без перебоев. Http OMG onion market 469. Чтобы зайти на ОМГ, вам нужно установить специальный браузер на своем компьютере. Новая ссылка ОМГ рабочий вход на OMG union в обход блокировки без ВПН и TOR. На Гидре было почти 500к сделок! Информация На сайте ОМГ помимо магазинов размещена и другая полезная информация по функционалу и вопросам безопасности, внимательно ознакомьтесь с правилами сайта! Как войти на OMG? VPN, Tor и прочие анонимайзеры все о безопасности ОМГ онион ссылка тор на русском.

После перечисленных действий перезапустите браузер. OMG магазин тор онион: OMG и OMG зеркала. Торговая площадка Omg Omg работает через Тор. Ссылка на ОМГ на зеркало. На ОМГ продаётся и продаётся. Нажимаем на него и переходим на официальный сайт ОМГ. Всегда сохраняйте рабочие ссылки и зеркала на Омг Омг. И если вы не можете зайти на основной сайт по какой-то причине, то попробуйте использовать зеркало. На нём вы найдете зеркала для браузеров Google Chrome и Mozilla, а также плагин, который позволяет зайти на ОМГ, минуя любые блокировки. OMG Onion (магазин ОМГ онион) новейшая торговая площадка в сети TOR. Например, можно использовать обычную банковскую карту с её помощью можно оплатить практически любые услуги, а можно расплачиваться непосредственно с помощью электронного кошелька. Mega Cсылка mega является одной из самых огромных торговых площадок на Даркнете в русском сегменте после закрытия сайта hydra. Помимо этого, на сайте представлены многочисленные категории, которые облегчают поиск продукции. После чего вы попадете на главную страницу главной страницы, на которой и находится ссылка на OMG onion. Но лучше посетить сайт. Если вы хотите зайти на Omg Omg сайт, вы должны знать, что у площадки предусмотрено несколько зеркал. Это сайт, который имеет внешнее отличие от оригинального сайта OMG. Ссылку, представленную выше, и перейти на сайт. Ссылки на ОМГ. Однако этот пробел можно устранить с помощью бота, который работает на автомате. После выбора страны можно указать номер телефона, на который придет SMS с кодом для подтверждения. ОМГ магазин онион. Именно поэтому сайт может долго загружаться или вообще зависнуть. OMG сайт для обхода блокировки роскомнадзора и официального зеркала магазина. Пополнить bitcoin на OMG bot можно любым удобным способом. Чтобы не было проблем, лучше устанавливать приложение с официального магазина. Это не только удобство, но и возможность найти нужный товар по лучшей цене. По умолчанию в Tor стоит браузер DuckDuckGo. С нами безопасно, деньги надежно хранятся на вашем счету. Чтобы попасть на сайт ОМГ, можно использовать Тор браузер. Как зайти на сайт ОМГ в обход блокировки моментальная площадка по продаже запрещенных товаров. Моментальный магазин OMG шоп На нашем сайте представлена актуальная информация о магазине ОМГ адрес, телефон и ссылка на ОМГ. Как зайти через браузер тор на сайт ОМГ ссылка ссылка на ОМГ в тор браузер скачать OMG onion. Поэтому настоящий сайт всегда легко отличить от подделки. БиСтафф 4400 сделок Просто. Вы можете скачать мобильное приложение Олимп на Андроид с официального сайта либо с Google Play Market. У многих возникает вопрос, а как же зайти на OMG магазин.